Shell-and-tube heat exchangers

Benefits

Fully customized to your requirements

Maximum uptime under the toughest operating conditions

High energy efficiency

Low maintenance requirements

Extensive service network

The Alfa Laval Olmi range of customized heat exchangers is designed and built for the toughest applications in chemical processing industries, oil & gas production and power stations. These units maximize plant sustainability through low service requirements and exceptional reliability, resulting in competitive total cost of ownership and trouble-free operation. And with our extensive offer of services, we can help you optimize operation throughout the entire product lifetime.

With an Alfa Laval Olmi process heat exchanger you get a tailor-made solution, optimized to your specific conditions. Our process heat exchangers are often used in production-critical positions under extreme conditions, and have a reputation for solid operating reliability and high performance.

Products

Hairpin multitube / double pipes

The hairpin multitube exchanger is the ideal solution to be installed in a limited space at site. This product allows our customers to have a wide choice on design data and metallurgy. The return elbow final closure is the critical step of construction. Our know-how and manufacturing experience for more than 80 years can guarantee our customers an excellent and reliable result.

Once-through cooler (OTC)

Over the last twenty years Alfa Laval Olmi has produced once-through coolers (OTC), resulting the best successful manufacturer since the first couple of OTC was born. Our creativity, courage and dedication allow us to be the first to develop a layout with circular tubes instead of the traditional straight tubes. The typical supply is composed of high-pressure and low-pressure equipment with different metallurgy. The final application is for power plants.

Process equipment

Alfa Laval Olmi process equipment is used for demanding heat transfer duties at refineries, power plants and chemical processing industries all over the world. We design and manufacture process solutions that are fully tailored to your requirements, e.g. with the ability to withstand extreme temperatures and pressures or corrosive process media. Our expertise in heat transfer, metallurgy and high-quality manufacturing ensure you get process solutions that will deliver high performance, reliable uptime and low operating costs for many years.

Quenching systems

Quench exchangers are core components in ethylene plants. These units operate under extremely tough conditions and are exposed to high flows of hot gas containing coke particles. Thanks to their unique designs, Alfa Laval Olmi quench exchangers are much more resistant to erosion, fouling, fatigue and corrosion than traditional quench exchangers.

Alfa Laval Olmi offers three different models of quench exchangers:

- Alfa Laval Olmi primary quench exchanger S&T type

- Alfa Laval Olmi primary quench exchanger double-pipe type

- Alfa Laval Olmi secondary and tertiary quench exchanger

Reactors

Reactors for chemical plants are manufactured in accordance with strict standards and the main calculation codes, applying our experience and know-how for the welding of several alloys (such as low chrome) and high alloys (such as nickel alloys).

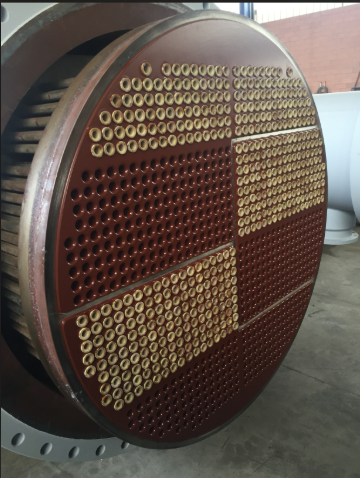

Tema type

We started manufacturing shell-and-tube heat exchangers in the early 60’s, applying a wide range of metallurgies, up to titanium alloys, nickel alloys, copper alloys, zirconium, etc., in combination with high-pressure and corrosive environments, also at temperatures above 600° C.

WHB system

With a full team of thermal and mechanical experts on board, we can take on and design our customers’ waste heat boilers by ensuring high reliability, low investments and the supply of the performance guarantee on the design data required by our customers. Our long experience in refractory application, as well as our know-how about the “no metal dusting” materials, can guarantee an excellent result in manufacturing of components subjected to high temperatures.

Unique features

ProShield

Secure uptime

The ProShield inlet on our double-pipe type quench exchanger does not suffer from the problems with coke growth and cracks in the Y inlet commonly found in similar quench exchangers. The highly effective cooling of the inlet and the short residence time dramatically reduce the difference in thermal expansion between the inner and the outer pipe, and the risk of fatigue cracks in the Y inlet. The superior cooling also eliminates the need for a thermal sleeve and does away with problems with coke migration and growth. The end result is a quench exchanger that offers long and reliable uptime in combination with low service requirements.

OptiForm

Ensuring reliable operation

The unique OptiForm tube sheet design gives Alfa Laval Olmi heat exchangers high resistance to erosion, corrosion and weld overheating. The first section of the tubes is an integral part of the tube sheet, machined after the plate has been forged. This means the welds connecting the tubes to the tube sheet are placed in the cooling medium, which protects them from overheating as well as impacting particles in the hot gas stream. The tube sheet surface is protected against the erosive hot gas by an Inconel layer, and the thin base plate allows for effective cooling and a low surface temperature. The result of these design innovations is exceptional durability and operating reliability compared to traditional tube sheets.

Case studies

Getting the job done in difficult times calls for new solutions

Just as an Italian Alfa Laval Olmi service team was finalizing preparations to go to Vår Energi’s offshore platform in Norway to upgrade an Alfa Laval Olmi shell-and-tube heat exchanger, the Covid-19 pandemic hit Europe. But despite travel bans and national lockdowns, the team managed to complete the service in time thanks to new collaborations and a strong customer focus.

Alfa Laval Olmi services heat exchangers in record time

See how Alfa Laval Olmi’s service specialists helped technicians at the Midor refinery in Egypt to perform service on four feed/effluent heat exchangers.